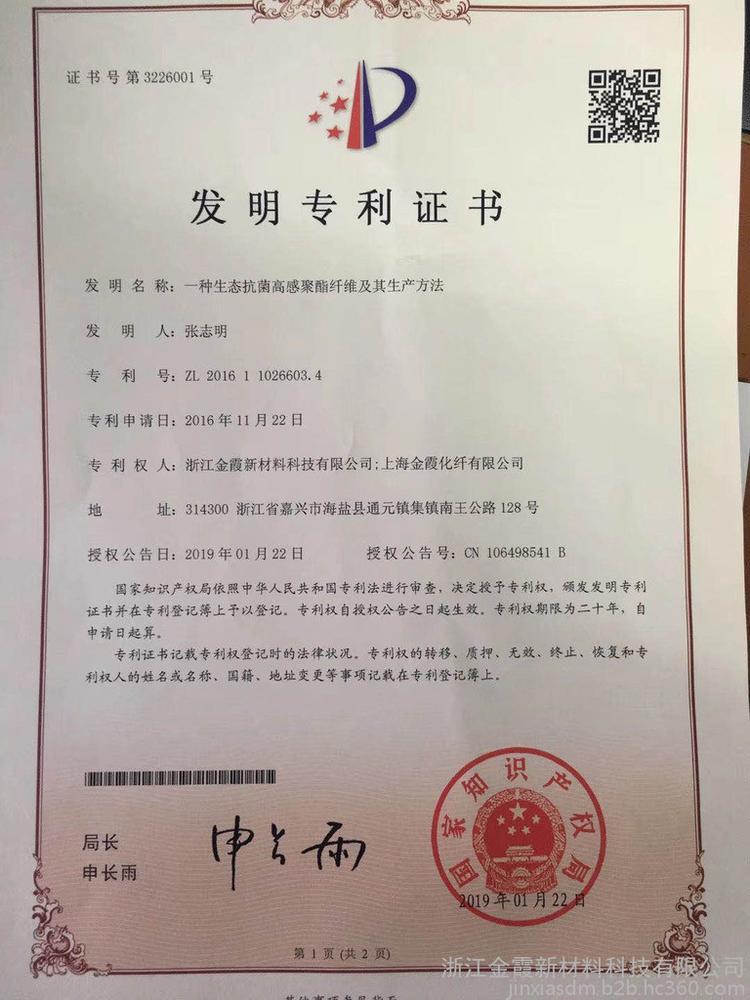

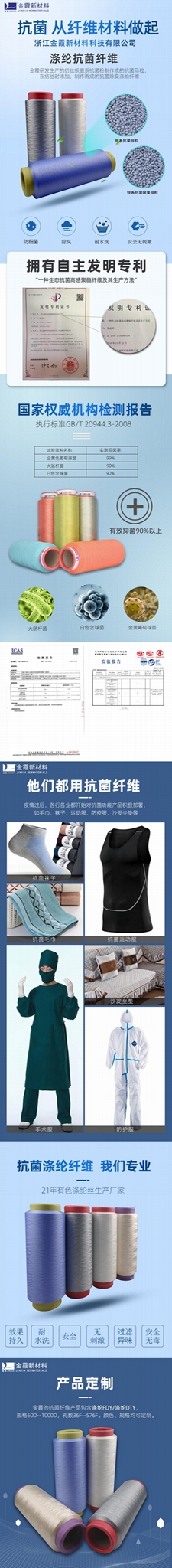

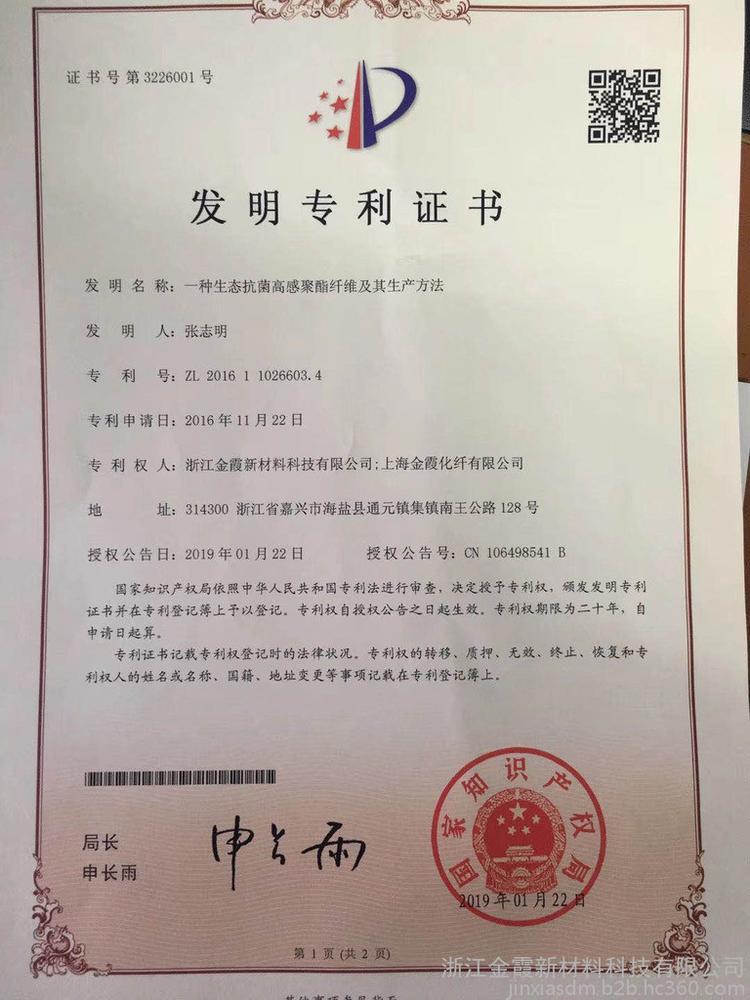

Product Description

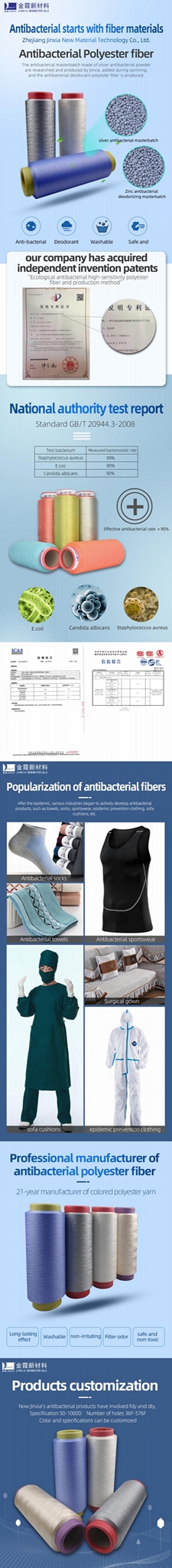

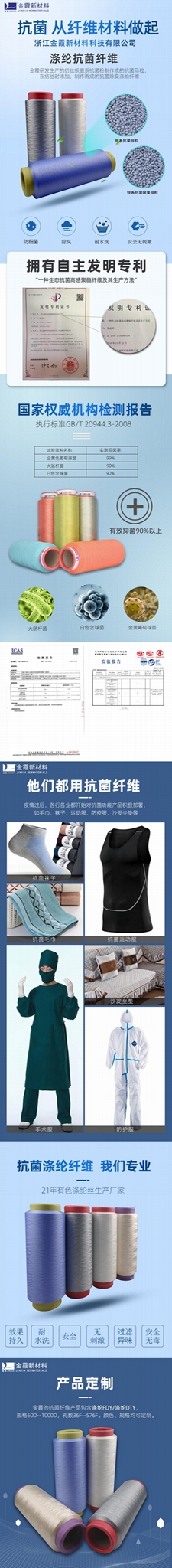

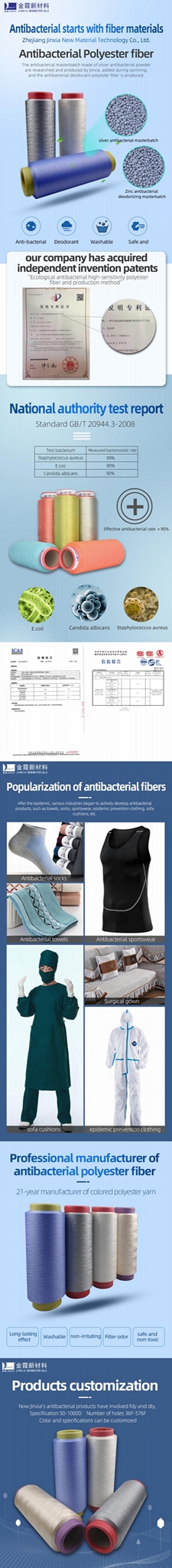

With the advent of the post-epidemic era, protection has become the new normal in daily life. Many scenes will use antibacterial and deodorant fabrics, such as masks, protective clothing, various textiles in the hospital, socks, underwear, bedding, and outdoor sports equipment . There are usually two methods for fabric antibacterial: the antibacterial deodorant yarn used in this fabric uses a built-in ion antibacterial process, and the antibacterial silver ions are directly incorporated into the fiber before spinning;

Antibacterial and deodorant yarn fabric

Fabric characteristics and antibacterial diagram

Another approach is to apply antibacterial and deodorant additives when the fabric is shaped. After the garment is washed for many times, the deodorant and antibacterial function will be weakened or disappear.

Finishing antibacterial and deodorizing fabric

Comparison of two antibacterial methods

Antibacterial tag

Test standards for antibacterial and deodorant fabrics

There are different standards such as American standard, national standard, European standard, and Japanese standard. At present, they are mainly divided into two categories: one is to detect specific values; for example, the antibacterial rate is 99.9%; the other is to issue logarithmic values, such as logarithmic values. 2.2, 3.8, etc. Usually the logarithmic value reaches 2.2 or more, which means that the test is qualified. The main bacterial species tested are: Staphylococcus aureus, Escherichia coli, methicillin-resistant Staphylococcus aureus MRSA, Klebsiella pneumoniae, fungi such as Candida albicans, and molds such as Aspergillus niger, globular chai, short budding Aureobasidium etc.

Antibacterial and deodorant fabric detection method

1. AATCC100 is the new antibacterial test (qualitative) standard for textiles. This standard is relatively strict. The result of the 24-hour evaluation is based on the bacterial reduction rate, which is similar to the sterilization standard. The Japanese and European standard detection methods are basically antibacterial detection, that is, the bacteria do not grow or weakly decrease after 24 hours to evaluate.

2. AATCC147 is a parallel line determination method, that is, to detect the antibacterial rate. This standard is mainly applicable to organic antibacterial agents. National standard GB/T20944, FZ/T72023, Japanese standard JIS L 1092, European standard: ISO20743.

Garment washing and maintenance: Garments can be machine washed, or hand-washed at room temperature, ironed and dried at low temperature

Storage and transportation: Moisture-proof and mildew-proof, prevent hanging with polyester clothing in summer to prevent color mixing.

Packing: fabric rolls, plastic bag, snake skin bag, double-layer plastic bag or plastic bag and carton.

The technical indicators are as follows:

Basic fabric information

Fabric number

TC015

Element%

T/C 60/40

JIS L1030

Width CM

147

ASTM D3774-1996

Gram weight G/SM

127

ASTM D 3776-9a C

Test items

Test result (Army Green)

Test Methods

Benchmark

Shrinkage rate

Warp -2.5%

Latitude -1.2%

AATCC 135-2018

≤3%

PH value

4.5

AATCC 8-2018

4-7.5

Color fastness to dry rubbing

4-5

AATCC 8-2018

≥4

Color fastness to wet rubbing

3-4

≥3

Color fastness to washing: color change

4-5

AATCC 61-(2A)2013

≥4

Color fastness to washing: stain

3-4

≥3

Color fastness to perspiration: color change

4-5

AATCC 107-2009

≥4

Color fastness to perspiration: stain

3-4

≥3

Antibacterial

conform to

JIS L 1902

Evaluation of bacteria not growing or weakly decreasing after 24 hours

Payment Terms︰

TT

SKU︰

50吨

custom_attr1︰

Polyester yarn with 99.9% moisture wicking and antibacterial effect

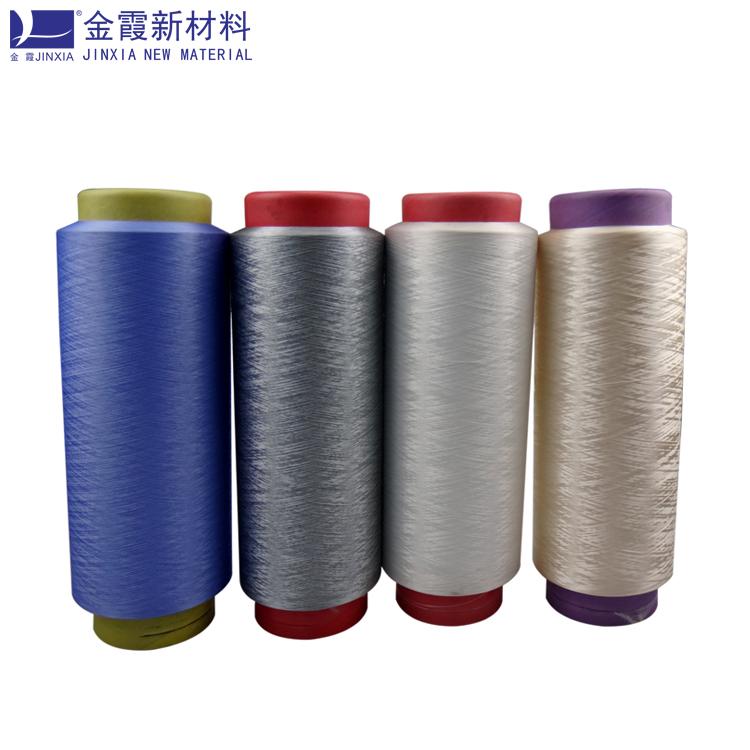

Product Image