The earth, the home of mankind's common existence, has been used up by human beings, and various resources are gradually exhausted. If human beings do not restrain themselves, they will be used up. With the arrival of the world environmental protection trend, green recycling has become a trend. In the textile industry, green production methods such as renewable and degradation have been advocated.

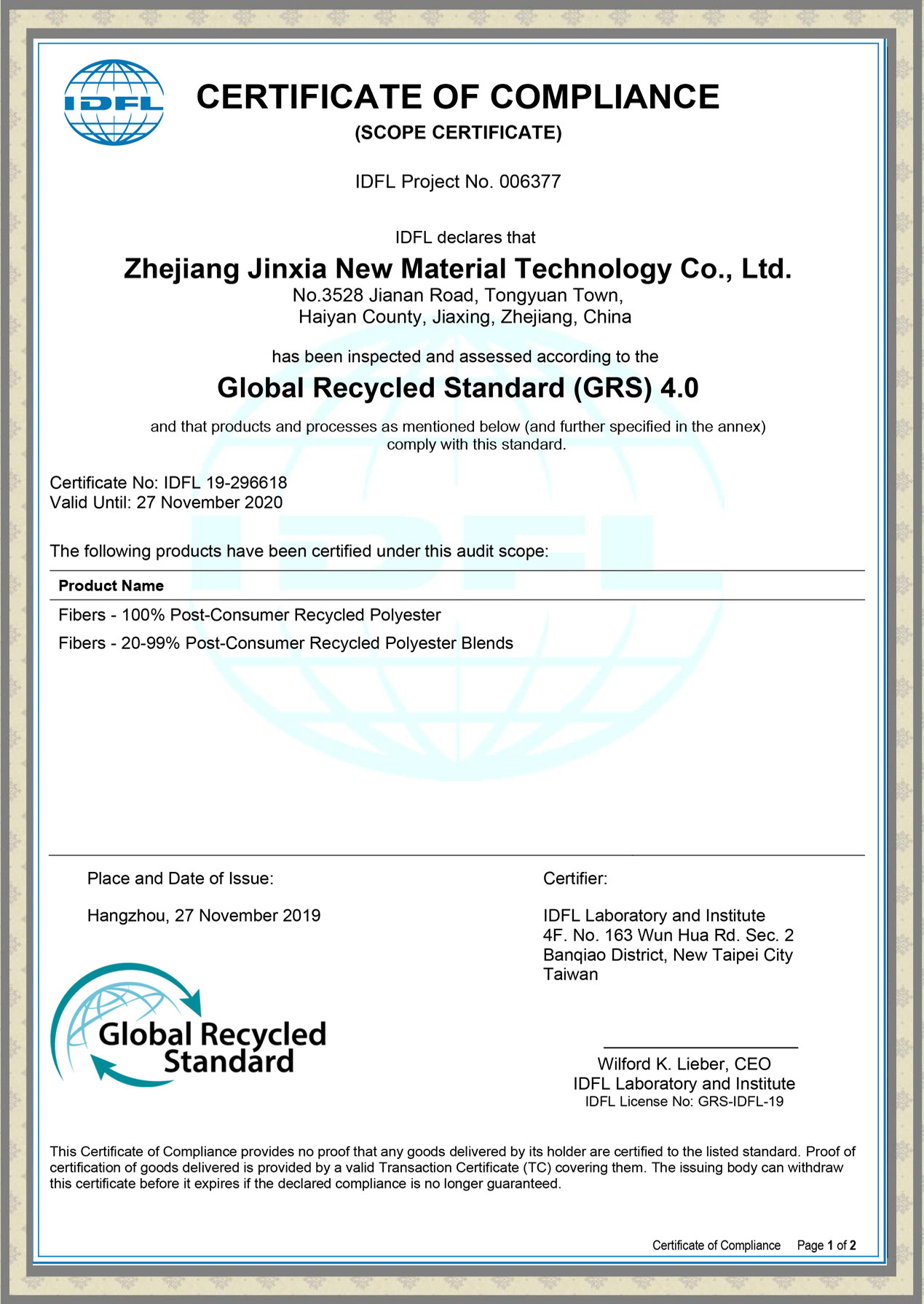

Colored recycled environmental protection polyester fiber is a technology of extracting regenerated polyester filament from plastic bottle, which is made of recycled polyester plastic bottle piece as raw material. The products are certified by international organizations, with GRS certificate and oeke certificate. The products are exported to European and American markets with guaranteed quality. The specifications range from 50D to 1000D; 24F to 576f; they can be customized, and the conventional production specifications are 75D / 72F 75D / 36F 150D / 48F 150D / 72F 150D / 144f 300D / 96F.

Recycling and recycling are widely used to reduce carbon dioxide. Among them, recycling PET beverage bottles into PET fiber is widely used in textiles. Recycling 1-liter beverage bottles can reduce carbon dioxide emissions by 0.042 kg. Every 20 PET bottles recovered can be processed into a T-shirt for summer wear

PET beverage bottle can be made into pet fragments by decapitation, label removal, washing, classification, crushing, flotation and other processes. PET chips can be made by granulation, melting and drawing. After processing, pet long fiber or short fiber can be made. The staple fiber is spun into yarn by spinning process.